Real-Time Data, Real Business Impact: How DeepIQ Enabled Operational Transformation at Grapevine Energy Holdings

Introduction

DeepIQ DataStudio has enabled real-time integration between our IT and OT systems, cutting our time to insights from days to minutes. It is a key enabler for how we operate and make decisions.

- Cole Norton, Senior VP of IT, Grapevine Energy Holdings

In a refinery environment, data is not just informational; it’s operational. At Grapevine Energy Holdings, LLC, refinery performance, safety, compliance, and delivery commitments depend on data flowing continuously and accurately across a complex landscape of control systems, maintenance platforms, and business applications.

When GEH launched its renewable diesel refinery operations, leadership made a strategic decision: operations would be 100% data-driven. To realize this vision, GEH partnered with DeepIQ to architect and deploy a real-time, cloud-native data integration platform. This platform seamlessly ingests and unifies diverse, high-velocity data streams—enabling continuous insights and powering every aspect of GEH’s operational decision-making.

DeepIQ’s Solution: An Integrated, Always-On Infrastructure

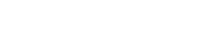

To provide a 360-degree view of the operations, DeepIQ implemented an enterprise-scale IT-OT data architecture using its DataStudio platform, integrated disparate systems such as:

- Honeywell PHD for process and control data

- IBM Maximo for asset and work order tracking

- Acumatica ERP for business operations

- OSI PI for real-time data infrastructure

Logistics, safety, and lab data

At the core of the architecture is a unified AWS-based data lake, built with a schema-on-read model for flexibility and scale. Data is continuously streamed from edge devices and enterprise systems, with 100% data residency retained in GEH’s tenant, ensuring both security and compliance.

A key innovation was the natural language interface, which enabled frontline teams and engineers to query and interact with data intuitively, without the need to write complex SQL queries or wait for IT support.

Real Use Cases Driving Business Value

Data Integration & Pipeline Orchestration

DeepIQ’s DataStudio platform powers real-time ingestion of over 150,000 operational signals every 15 minutes into a centralized AWS data lake. By automating the flow of data across control systems, ERP, and maintenance platforms, GEH streamlined pipeline management and enabled continuous operations monitoring—all with full data residency and compliance.

System Integration for Maintenance Operations

DeepIQ connected IBM Maximo’s work management with Acumatica ERP’s inventory system to ensure that maintenance tasks are dynamically informed by real-time part availability and asset status. This eliminated manual coordination, reduced asset downtime, and improved planning accuracy across the refinery.

Executive Dashboards & Operational Context

Using Power BI and automated distribution workflows, GEH executives receive daily dashboards that combine real-time KPIs (e.g., production, tank levels) with embedded field-level insights. These reports support high-speed, informed decision-making by uniting analytics with frontline commentary.

Business Outcomes

By implementing an integrated, cloud-native data infrastructure with DeepIQ, GEH has achieved measurable operational improvements:

- Real-Time Operational Awareness: Continuous data ingestion and monitoring across production, maintenance, and logistics systems has given teams immediate visibility into performance and anomalies—enabling quick corrective actions before disruptions occur.

- Streamlined Decision-Making: Executive dashboards deliver live KPIs enriched with on-the-ground context, ensuring leaders have both the metrics and narrative needed to make confident, timely decisions.

- Improved Maintenance Coordination: Integration between work orders and inventory systems has eliminated manual planning gaps, reduced asset downtime and enhanced overall operational reliability.